8 Common Printing Processes

Screen Printing

It can be operated on flat objects, spherical objects, curved objects, and even concave and convex surfaces. For example, clothes, wood, etc. can be printed, with great flexibility. After printing, the ink layer is thick and the three-dimensional effect is strong. The screen printing process equipment is simple, the operation is convenient, the printing and plate making are simple, the cost is low, and the adaptability is strong.

Gold stamping / hot silver:

It is called hot pressing transfer printing, referred to as thermal pad printing, commonly known as hot stamping and hot silver. It is a method of hot stamping metal foil onto printed matter by means of a certain pressure and temperature.

It can be combined with the embossing or embossing process, and the effect will be better; in addition to gold and silver, the colors that can be used include color gold, laser light, spot colors, etc.

UV:

It is the above-mentioned ultraviolet varnishing, UV is the abbreviation,the curing ink can be dried by ultraviolet radiation. UV is usually a screen printing process, and now there is also offset UV. If you use UV on the film, you need to use a special UV film, otherwise the UV is easy to fall off, foaming and other phenomena, and the effect of special processes such as bulging and bronzing is better.

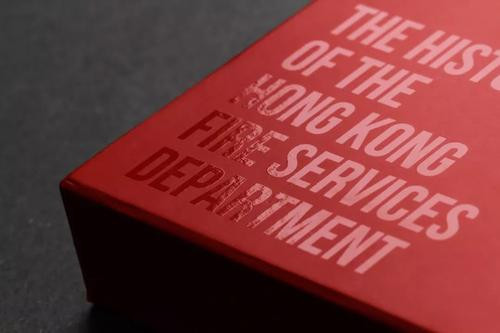

Emboss:

It is to use a convex template (positive template) to emboss the surface of the printed matter into a three-dimensional relief-like pattern through pressure (the printed matter is partially raised, making it three-dimensional and causing visual impact.) It is called convexity; it can increase the three-dimensional effect. It needs to be made on paper of more than 200g, high gram weight special paper with obvious mechanism sense.

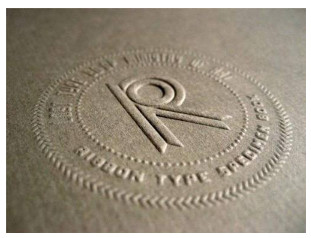

Deboss:

It is to use a concave template (negative template) to press the surface of the printed matter into a relief-like pattern with a concave feeling (the printed matter is partially concave, making it a three-dimensional feeling and causing a visual impact.) It can also increase the three-dimensional feeling. Paper requirements Same as bulge. Both convex and concave can be matched with bronzing, partial UV and other processes.

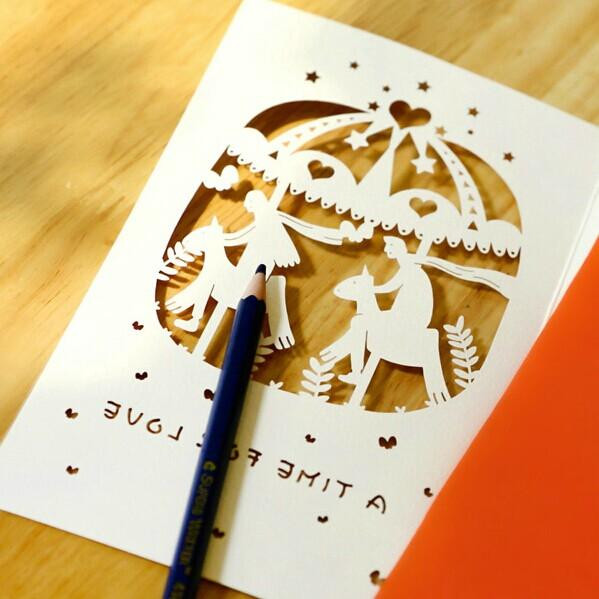

Die Cutting

The die-cutting process is a molding process in which a special die-cutting knife is made according to the design requirements of the printed matter, and then the printed matter or other substrates are rolled into the desired shape or incision under the action of pressure.

It is suitable for products with more than 150g paper as raw material, try to avoid patterns and lines close to the tangent line

Lamination:

Laminate a layer of transparent plastic film on the printed paper, including crystal film, light film and matte film, which are called differently in many places and are not environmentally friendly.

Flocking:

It is to brush a layer of glue on the paper, and then paste a layer of fluff-like material to make the paper look and feel a little flannel.

Brush edge:

It is to brush an extra layer of color on the edge of the paper, which is suitable for thicker paper and is often used for business cards.

Post time: Jun-17-2022